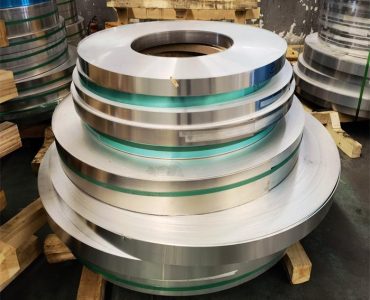

Aluminum strip has emerged as a remarkable material with a multitude of applications across various industries, revolutionizing the way we approach modern manufacturing. Its unique combination of properties makes it a go-to choice for a wide range of industrial needs. In this article, we delve into the versatility of aluminum strip and its extensive applications that contribute to efficiency, sustainability, and innovation.

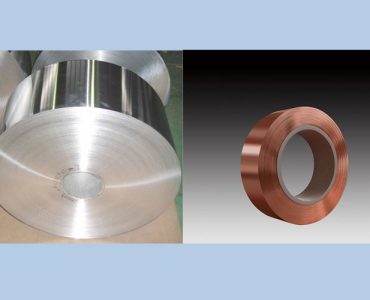

1. Electrical and Electronics:

Aluminum strip plays a pivotal role in the electrical and electronics sectors. Its excellent electrical conductivity makes it an ideal material for transformer windings, electrical coils, and conductors. Moreover, its lightweight nature is a valuable asset in industries that require efficient heat dissipation, such as heat sinks in electronic devices.

2. Construction and Architecture:

The construction industry benefits immensely from the use of aluminum strip. It is a popular choice for manufacturing window frames, roofing components, and decorative trims due to its lightweight construction, corrosion resistance, and modern aesthetics.

3. Automotive Manufacturing:

In the automotive sector, aluminum strip is a game-changer. It’s widely employed in the production of heat exchangers, radiators, and various engine components. The lightweight nature of aluminum contributes to improved fuel efficiency and overall vehicle performance.

4. Packaging Solutions:

Aluminum strip is an integral part of modern packaging solutions. Its malleability allows for the creation of seals, lids, and closures for containers, ensuring product integrity and freshness.

5. Aerospace Industry:

The aerospace industry demands materials that are both lightweight and durable. Aluminum strip fits the bill perfectly, finding applications in aircraft components, structural elements, and even in satellites.

6. Renewable Energy:

Aluminum strip plays a role in advancing renewable energy technologies. It is utilized in solar panels and other energy systems for its high thermal conductivity and resistance to corrosion.

7. Manufacturing and Machinery:

In manufacturing and industrial machinery, aluminum strip finds its place in various components due to its exceptional formability, strength, and resistance to wear and tear.

8. Marine and Coastal Applications:

Corrosion resistance makes aluminum strip invaluable in marine and coastal applications. From shipbuilding to offshore structures, aluminum proves its mettle against the challenges of saltwater environments.

9. Consumer Goods and Appliances:

The consumer goods industry benefits from aluminum strip in the production of appliances, cookware, and other household items. Its aesthetic appeal, lightness, and corrosion resistance contribute to the durability and attractiveness of such products.

10. Custom Innovations:

Beyond these established sectors, aluminum strip continues to inspire custom innovations. Its versatility allows engineers and designers to push boundaries and create novel solutions for emerging challenges.

Conclusion:

Aluminum strip’s versatility extends far and wide, making it an indispensable component in countless industrial applications. Its unique combination of properties, including lightweight construction, electrical and thermal conductivity, corrosion resistance, and formability, positions it as a versatile solution that drives progress and innovation across industries. As technology evolves and industries continue to seek efficient and sustainable materials, aluminum strip remains at the forefront of modern industrial solutions.