When it comes to aluminum materials, the choice between aluminum strip and aluminum sheet can significantly impact the success of your project. Both options offer unique properties and advantages, catering to different applications and requirements. Here’s a comparison to help you make an informed decision:

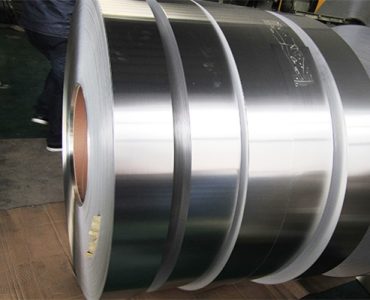

Aluminum Strip:

Aluminum strip is characterized by its narrow width and relatively thin thickness. It is a versatile choice for projects that demand precision and flexibility. Here are its key features and ideal applications:

- Precision Components: Aluminum strips are ideal for creating precision components, such as electrical coils, transformer windings, and heat exchanger fins. Their narrow width allows for intricate designs and efficient utilization of space.

- Electrical and Thermal Applications: If your project requires efficient electrical conductivity or heat dissipation, aluminum strips are well-suited. They are commonly used in power transmission, electronics, and thermal management systems.

- Formability: Aluminum strips are highly formable, making them suitable for applications where shaping or bending is required, such as architectural trims and automotive components.

Aluminum Sheet:

Aluminum sheet, on the other hand, is characterized by its larger width and thickness. It offers strength, durability, and a wider surface area. Here’s what makes aluminum sheet an excellent choice and its ideal applications:

- Structural Components: Aluminum sheets are commonly used for structural components in construction, aerospace, and automotive industries. They provide strength and stability, making them suitable for load-bearing applications.

- Large Surfaces: If your project requires larger surfaces or panels, aluminum sheets provide the necessary area coverage. They are used for roofing, cladding, and façade applications.

- Flatness and Surface Finish: Aluminum sheets often have a smoother surface finish compared to strips. This makes them suitable for applications where aesthetics and appearance are important.

Choosing the Right Option:

Ultimately, the choice between aluminum strip and aluminum sheet depends on your project’s specific needs. Consider factors such as the desired dimensions, strength requirements, formability, conductivity, heat dissipation, and surface finish. If precision, flexibility, and efficient use of space are essential, aluminum strip may be ideal. On the other hand, if your project demands strength, larger surface coverage, or structural integrity, aluminum sheet is a suitable choice. Consulting with experts in aluminum materials can provide valuable insights tailored to your application, helping you make the optimal decision for your project’s success.