As industries evolve and market dynamics shift, staying updated with the latest price trends is crucial for businesses and individuals seeking quality aluminium strips for their projects.

The aluminum strip market is known for its fluctuating prices influenced by factors such as raw material costs, demand, and global economic conditions.

In this special page, we delve into the intricacies of the aluminum strip market, providing you with insights into the latest price trends and the factors that drive them.

Understanding Aluminum Strip Pricing:

The price of aluminium strips is influenced by various variables, including the alloy type, thickness, width, length, and grade. Market conditions, supply chain disruptions, and geopolitical factors also contribute to price fluctuations. It’s essential to recognize that aluminum, being a globally traded commodity, is subject to changes in international trade dynamics that impact its cost.

Factors Driving Price Changes:

- Raw Material Costs: Fluctuations in the cost of raw materials used in aluminum production can directly impact the price of aluminum strips. These materials include bauxite, alumina, and energy sources required for the smelting process.

- Global Demand: Industries such as construction, automotive, and electronics are major consumers of aluminum strips. Changes in demand within these sectors can drive prices up or down.

- Trade Policies: International trade policies, tariffs, and trade agreements can influence the flow of aluminum and subsequently impact prices.

- Economic Conditions: Economic factors, both global and regional, play a significant role. Economic growth can increase demand, leading to price rises.

Navigating Price Fluctuations:

Given the dynamic nature of the aluminum strip market, businesses and consumers can employ strategies to navigate price fluctuations effectively:

- Monitoring Trends: Regularly keeping track of price trends and market forecasts enables informed decision-making.

- Supplier Relationships: Building strong relationships with reliable suppliers can provide insights and opportunities to secure competitive prices.

- Diversified Sourcing: Exploring multiple suppliers and sources can help mitigate supply chain disruptions and maintain stable pricing.

- Adaptive Planning: Incorporating flexibility into project planning allows for adjustments in case of unexpected price changes.

Understanding the latest price trends in the aluminum strip market empowers businesses and individuals to make informed choices aligned with their project needs and budget considerations. While price fluctuations are inevitable, staying informed and proactive helps mitigate potential challenges and capitalize on favorable market conditions.

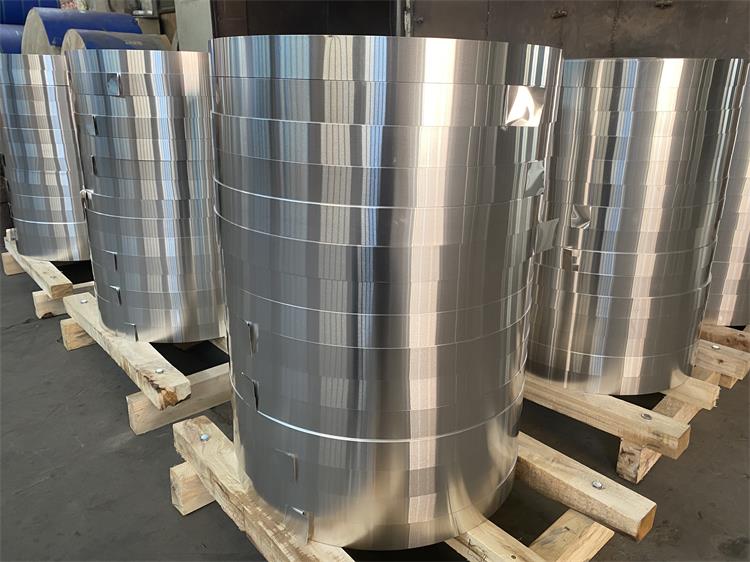

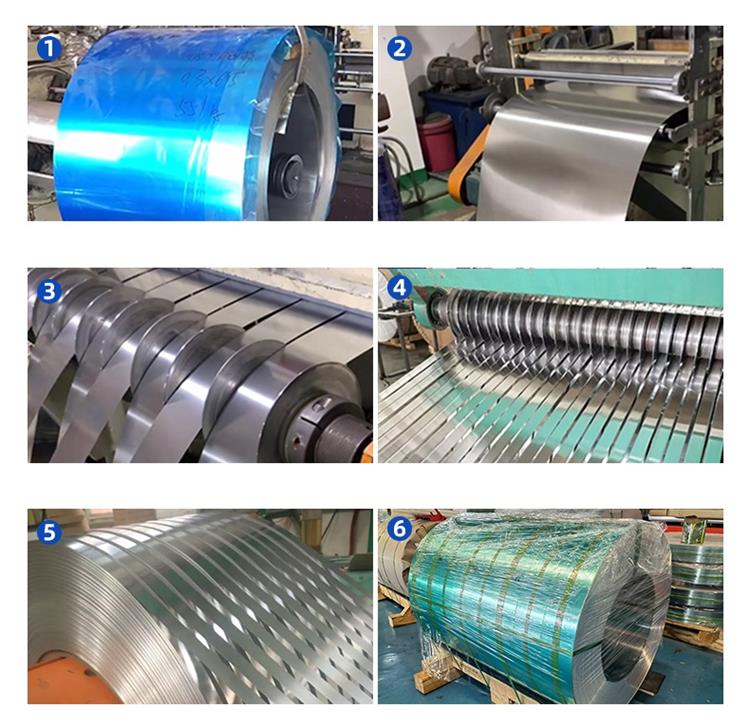

Production Process and Equipment

The production process and equipment used in manufacturing aluminum strips play a significant role in determining their price. Here’s how these factors are related to the pricing of aluminum strips:

1. Production Process Efficiency: The efficiency of the production process directly impacts the cost of producing aluminum strips. Modern, streamlined production processes that optimize resource utilization, minimize waste, and reduce energy consumption tend to result in more competitive prices. Manufacturers that invest in advanced technologies and process improvements can often offer more cost-effective products.

2. Raw Material Quality and Source: The quality and source of raw materials used in the production of aluminum strips can affect the final product’s price. Higher-quality raw materials might yield strips with superior properties, but they can also come at a higher cost. Additionally, the availability of these raw materials can influence prices due to supply-demand dynamics.

3. Production Scale and Volume: Economies of scale play a crucial role in pricing. Larger production volumes often lead to lower per-unit production costs, allowing manufacturers to offer more competitive prices to customers. High-volume production can help spread fixed costs across a larger number of units, contributing to price efficiency.

4. Automation and Technology: The level of automation and technology used in the production process can impact labor costs and production efficiency. Automated equipment can enhance precision, reduce human error, and increase throughput, all of which contribute to cost savings that can be passed on to customers.

5. Energy Efficiency: Energy costs are a significant factor in aluminum production. Manufacturers that use energy-efficient equipment and processes can benefit from reduced operational costs, which can translate to more competitive pricing for their aluminum strips.

6. Production Equipment Investment: The type and quality of production equipment used also affect pricing. Investment in modern equipment can lead to higher productivity, fewer defects, and better quality control. However, the initial investment in advanced equipment might be reflected in the product’s price.

7. Environmental Regulations and Compliance: Compliance with environmental regulations can influence production costs. Manufacturers that invest in environmentally friendly practices and technologies might incur additional expenses, which can impact the price of the final product.

8. Research and Development: Manufacturers that invest in research and development to improve the properties or applications of aluminum strips may have higher production costs, but the resulting enhanced product quality could justify a higher price.

In summary, the production process and equipment directly influence the cost structure of aluminum strips. Manufacturers that prioritize efficiency, quality, and innovation in their production processes tend to be better positioned to offer competitive pricing while delivering a high-quality product.

Price Calculation Formula

Aluminum strip price = aluminum ingot price on the day + aluminum strip processing cost, unit: per kilogram

This formula is a very simple and intuitive explanation of the price structure of aluminum strips, allowing users to purchase our aluminum strip series clearly and with confidence.

FAQs – Aluminum Strip Prices:

1. What factors influence the price of aluminum strips?

- The price of aluminum strips is influenced by factors such as global supply and demand dynamics, such as alloy type, thickness, width, length, and market fluctuations.

2. How often are the prices updated?

- Our prices are updated every two days, taking into account the global time difference

3. What payment methods are accepted for aluminum strip purchases?

- The payment methods we accept are LC, TT

4. How do I place an order for aluminum strips?

- Communication – sign a contract -> place an order at the factory -> track the production progress of goods -> order warehouse -> deliver goods -> make documents -> receive goods -> after sales

5. How can I contact customer support for further pricing-related questions?

- You can get in touch with us by email and WhatsApp

In the world of industrial materials, the price of aluminum strips holds a mirror to the intricacies of global markets, supply chains, and technological advancements.

As we’ve explored, aluminum strip pricing is a multifaceted landscape influenced by a myriad of factors, each playing a distinct role in determining the cost.

From the alloy composition to the thickness, from the production process to the state of the global economy – every aspect contributes to the final price tag.

Staying informed about the latest price trends and understanding the factors driving these fluctuations is an essential practice for businesses and individuals alike. It empowers decision-makers to make informed choices, aligning projects with budgetary considerations and ensuring optimal value for every investment.